bluebee®: connecting to external devices with Bluetooth

Technology is opening new possibilities, unheard of only a few years ago. Drawing on its experience in both mobile maintenance solutions and condition monitoring, Siveco has designed an integration between bluebee® and external devices using the Bluetooth connectivity.

This seemingly simple approach represents a major improvement on currently available solutions that required manual input of readings or expensive condition monitoring devices running Windows Mobile or Android OS.

The connected solution

Technicians are equipped with bluebee® devices, used to manage inspections and preventive maintenance, as well as corrective maintenance (non-conformity and fault reports, handling of corrective work orders). In the typical industrial environment, bluebee® runs on rugged industrial PDA devices (also provided by Siveco), available in explosive-proof ATEX-certified versions. In lighter office-like environments, bluebee® runs on tablet PC or consumer-grade smartphone devices. In any case, those devices do not include measurement sensors.

Technician using bluebee®

When required to take measurements (typically vibration, rounds-per-minute, temperature), technicians carry an external measurement device, a data-collector featuring built-in sensors for the five most important machine condition parameters:

1 – Vibration severity

2 – Bearing condition

3 – Rotational speed

4 – Temperature

5 – Pump cavitation

2 – Bearing condition

3 – Rotational speed

4 – Temperature

5 – Pump cavitation

The device is designed for industrial environment and also available in ATEX-certified versions. It also features connectors for external temperature and vibration probes, which may pre-installed on important equipment.

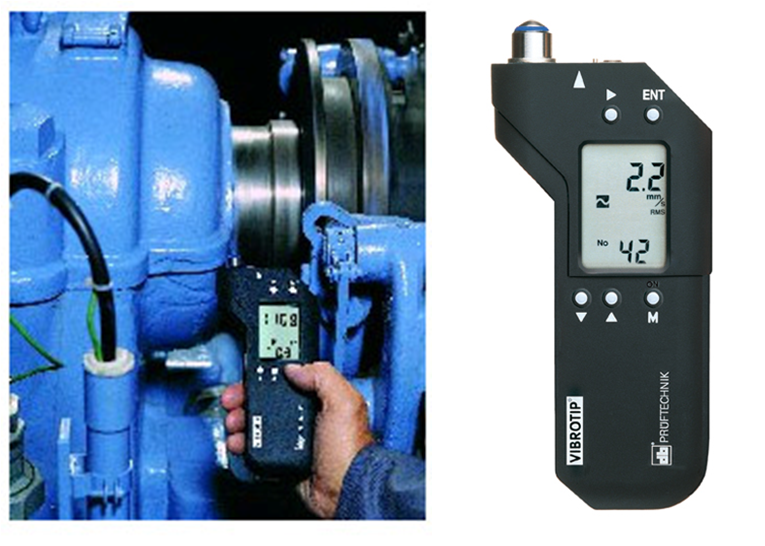

An example of Bluetooth-enabled data collector is VIBROTIP by German condition-monitoring specialist Prüftechnik

The data collector automatically connects to bluebee® (which may remain in the pocket or in a holster on the worker’s belt) via the Bluetooth connection to upload all data, which is then combined with bluebee® data such as pictures, notes and other inspection results and finally synchronized into the central database (bluebee® cloud).

In the back-office, measurements can be processed in bluebee® cloud (trending, alarms and risk levels, comparison with other historical maintenance data such as replacements, failures etc.) or passed onto a specialized vibration analysis software for further analysis (spectrum analysis etc.).

Similar integration can also be done with other Bluetooth-enabled devices.

Benefits

The benefits of this approach are numerous.

From a system integration point-of-view, the solution is simple as it relies on widely spread technologies, now available in all kind of consumer devices, from mobile phones, laptop computers, cars etc. On the back-office side, bluebee® cloud also transfers data to specialized condition monitoring software using standard SQL technologies. The entire integration is 100% standard and does not require specific development.

From a cost perspective, it avoids the use of expensive handheld devices that combine the features of measurement instruments and mobile devices, two fundamentally different types of equipment. Instead, two simpler devices are used, which is both cheaper and more reliable (if the instrument is broken, it can easily be replaced by a back-up instrument and the bluebee® device is in any case not affected).

For end-users, while most technicians may be equipped with bluebee®, only few of them will, less frequently, use instruments, which can then be pooled and shared among technicians. The data logger is simple to use and requires very little training, unlike more complex instruments. It is also small and lightweight, can fit in a pocket and go unnoticed (as a mobile phone would).

From a maintenance improvement perspective, which is the goal of all projects, this combined approach helps run condition monitoring projects in complete coordination with other types of inspections, within the overall maintenance strategy process. This is often forgotten and many condition monitoring instruments are left to collect dust on the shelf as a result.

As a maintenance engineering consultancy, Siveco has in-depth expertise in both mobility / field service projects and condition monitoring. Siveco can integrate all elements of a project: maintenance consulting, system implementation services, the back-office maintenance management solution, the mobile software (bluebee®), condition monitoring instruments and analysis software, all the hardware required (mobile devices and Bluetooth-enabled instruments), as well as longer-term coaching and support services.