How Baida Air unified its multisite operations with Coswin 8i

Beijing Baida Air Co., Ltd.

Beijing Baida Air (www.baidaair.com.cn), is a specialized company established in 2010 to supply oxygen to industrial clients using vacuum-pressure swing adsorption (VPSA) technology. This technology can be applied widely in the fields of fiberglass, glass, steel, nonferrous metals, recycled metals, coal gasification, sewage treatment and other industrial applications of oxygen.

Through its strategy of specialization, Baida Air is 100% dedicated to become the leader in VPSA oxygen supply. Focused on providing long-term value based on customers’ needs, with a partnership approach to development, Baida Air has already, six years after its creation, invested, built and now operates oxygen plants in Sichuan, Jiangsu, Shandong, Fujian, Jiangxi and other provinces. With plant scale ranging from 1500Nm3/h to 12500Nm3/h (the largest domestic VPSA oxygen supply project), Baida Air has become one of the largest player in the field.

Competing with international gas suppliers, Baida Air has always operated its plants in line with international standards. To ensure high reliability, low energy consumption, smooth operations and other technical advantages, Baida Air has deployed multisite fault diagnosis solutions, supervision systems, maintenance management systems and set-up a reliability technology center, also relying on third-party technical support when needed. The company’s reliability and safety in gas operations has passed the most stringent industry tests and been recognized by clients, setting new benchmarks for domestic pressure swing absorption oxygen in terms of management and technology.

Ensuring reliable and safe gas supply, while continuously reducing oxygen cost for customers, remain Baida Air’s continuing mission!

The CMMS project

When the project was initiated, Baida Air already had three plants in operation and was developing aggressively in the market. As the company expanded, multisite technical management started to become critical. To fulfill its industrial objectives, Baida Air required an easy-to-expand maintenance management system (CMMS).

After several technical exchanges and visits to reference sites, followed by a formal bidding process, Siveco was identified as the most suitable supplier with its Coswin 8i CMMS. A pilot site was selected: Sichuan Baida Industrial Gas, located in Luojiang, Sichuan province.

Project objectives

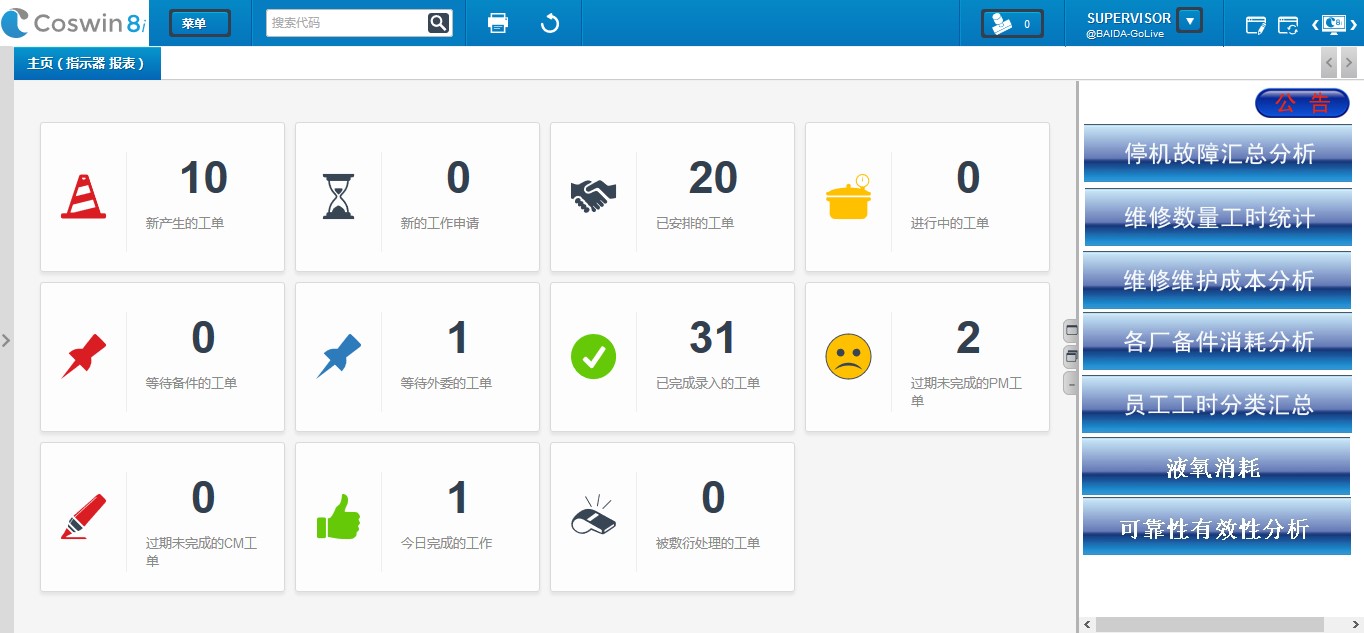

The main objective of the project was to build an easy-to-use maintenance management platform for Baida Air multiple sites. The first step was to establish the technical equipment database and related maintenance procedures knowledge base. Then, through the CMMS, to implement and optimize the maintenance plan and to report the various types of work performed in plants. Finally, by tracking on-site equipment operations in real-time, detailed analysis would become possible for technical management and decision making.

All in all, the CMMS must provide technical and managerial support for the following:

• Plants technical database and document management system

• Build up and training of the maintenance team for new plants

• Maintenance historical knowledge base for technical analysis and diagnosis

• Headquarters’ KPIs and reporting system, allowing benchmarking

• Setup and implementation of preventive maintenance

• Build up and training of the maintenance team for new plants

• Maintenance historical knowledge base for technical analysis and diagnosis

• Headquarters’ KPIs and reporting system, allowing benchmarking

• Setup and implementation of preventive maintenance

The Siveco project

The project was kick-off on June 18, 2014 by Baida Air technical director and the Siveco project team. On August 25, 2014 the CMMS went “live”.

At the beginning of the project, the Siveco team conducted an in-depth implementation study, documented in a group-level “Core Model” for Baida Air. The document describes how the Coswin 8i maintenance management system will be implemented, providing a quick and easy guideline for future deployment and support.

The Coswin 8i platform was installed on a central cloud server, to which all Baida Air plants can access through a secured internet connection.

The project team then guided the data collection process for the pilot site in Sichuan. Data was imported into Coswin 8i, forming an asset technical database to support the daily work of engineers.

Through systematic records of failures and corrective maintenance actions, Coswin 8i gradually builds up a historical database of maintenance for technical analysis purposes.

For preventive maintenance, Baida Air uses Coswin 8i automatic planning functions. Based on predefined templates, the CMMS automatically generates preventive maintenance plans and issues work orders, ensuring rapid and accurate planning.

Coswin 8i system multi-site inventory functions allow a unified management of spare parts. Quantities available in the different plants are visible to all, ensuring optimized stock levels.

Different Baida Air users have different KPIs. Based on work reports from the plants, the CMMS automatically generates KPIs and standard reports on a monthly basis. Baida Air users can view different categories of reports as needed.

Upon completion of the pilot, Coswin 8i was immediately rolled out to all the other sites.

Project results

According to Lu Jun, General Manager of Baida Air:

“Coswin 8i helped Baida Air achieve its goal of unifying the management of all its plants, providing immediate visibility into organization structures, assets database and spare parts stocks across sites.”

Since Coswin 8i was implemented, each plant systematically records maintenance work and receives effective support for maintenance and operation improvement decisions.

During monthly meetings, by reviewing reports such as: reliability analysis, downtime reports, maintenance cost tracking and employee hours, Baida Air managers and engineers can assess the operating condition of each plant and the impact of maintenance actions in a timely and accurate manner.

All project objectives were met.

Future developments

Baida Gas continues to grow its business in Sichuan, Jiangsu, Shandong, Fujian, Jiangxi and other provinces, investing in, building and operating new oxygen plants. Each new plant deploys Coswin 8i to achieve compliance with the group’s standardized operation and maintenance, thus ensuring reliable and efficient production.