MANE Fragrance & Flavour ensures traceability, streamlines compliance audits with Maintenance 4.0

Background

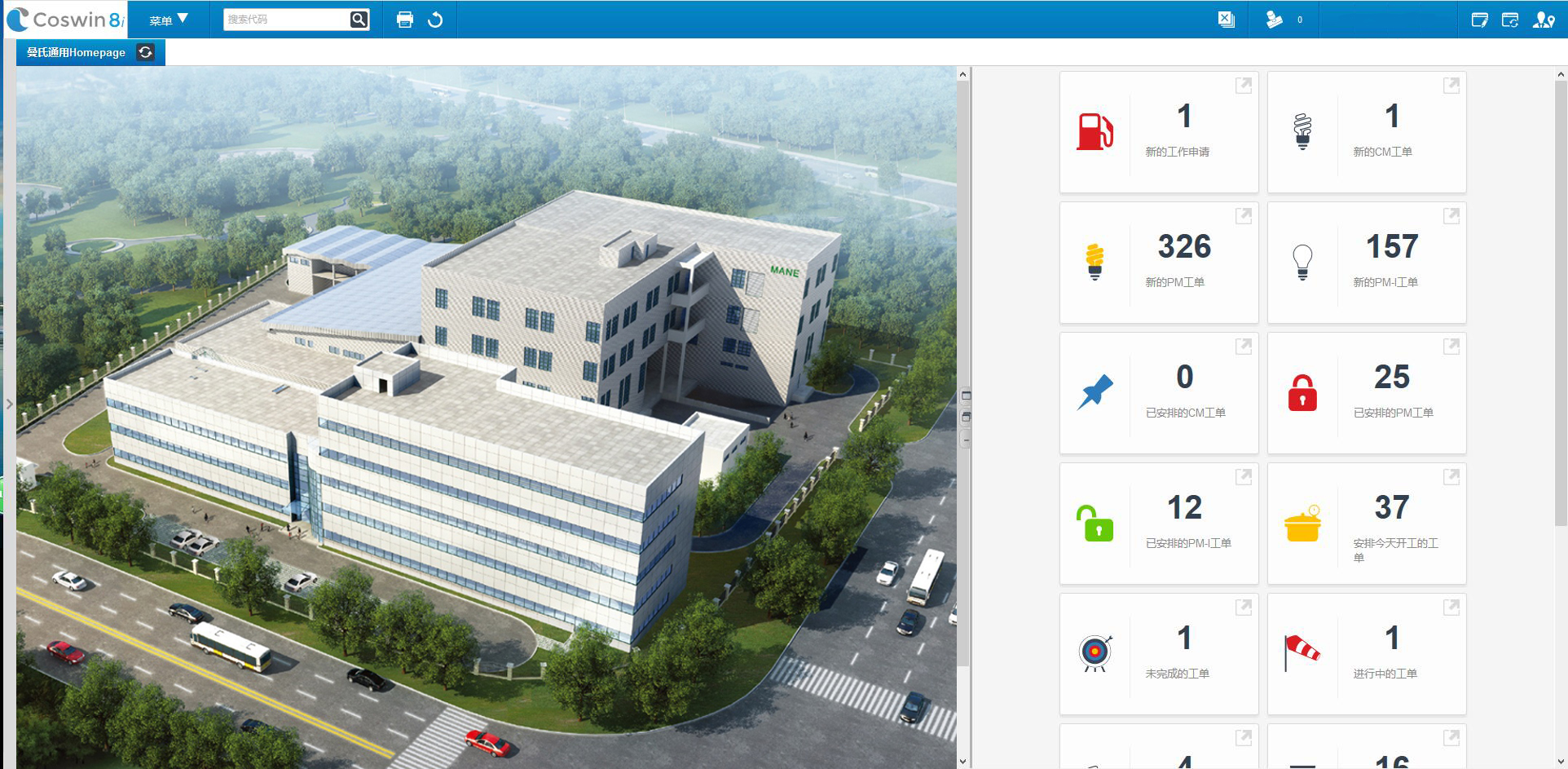

MANE (www.mane.com), one of the worldwide leaders in the fragrance and flavour industry, has been operating in China for close to 20 years. With offices in Beijing, Shanghai and Guangzhou, as well as a production plant and R&D center in Shanghai, MANE (Shanghai) Fragrances and Flavours Co., Ltd. is MANE’s affiliate covering China, Hong Kong, Taiwan and Korea. MANE’s existing factory – phases 1 & 2 – is located in the Shanghai Baoshan City Industrial Park. To accommodate continuous growth in China, MANE is investing in the construction of its third industrial phase in the Pinghu industrial zone of Zhejiang province. In 2014, MANE Shanghai selected Siveco to implement a maintenance management system and mobile inspection solution at its Shanghai production plant.

The project: structuring maintenance around a modern IT system

After the initial implementation study conducted in 2014, Siveco’s Maintenance 4.0 solution was implemented with the goal of supporting the establishment of a systematic and sustainable maintenance organization at the Shanghai plant.

The project was structured around the ISO 55000 Asset Management framework (GB/T 33172 in its Chinese version) to ensure comprehensive coverage in compliance with the highest international standards. As part of the implementation process, the joint MANE-Siveco project team defined coding rules and structures and established a complete equipment information database. Workflows were streamlined and the spare parts management process was optimized.

The system itself was setup to support the maintenance organization: all work planning, execution and reporting being carried out in the system using bluebee®.

The Maintenance 4.0 system was put into operation in September 2014. As a result, maintenance analysis can be conducted monthly based on accurate data from technicians.

The bluebee® upgrade: keeping up with technological changes

One of the challenges of mobile technology in industrials settings is its rapid pace of change. Siveco has been able to keep up and anticipate these changes by investing heavily in mobile development, setting up a dedicated R&D center in Shanghai in 2008. When the project was launched in 2014, all the industrial-grade devices available on the market were running the Microsoft Windows Mobile operating system and the corresponding version of bluebee® was installed.

In 2016, in view of MANE’s evolving needs and newly available technologies, an upgrade and improvement project was carried out. The PDAs were discarded to be replaced by normal smartphones running the Android version of bluebee®. In addition, bluebee® for WeChat has also been implemented, allowing anyone whose mobile phone is connected to the company network to report problems into the central database, with attached photos. This major technological change was handled as an upgrade (no new software license required) since MANE was constantly under the Siveco support program.

This upgrade greatly improved users’ motivation. The more natural Android and WeChat-based user interface allows for a more intuitive usage, timely and accurate reporting of incidents and work done.

In September 2016, the upgrade Go Live ceremony was held. During the ceremony, Siveco’s Operation Director Guillaume gave a welcome speech, emphasizing the use of the system at MANE both as a compliance management tool and as an improvement tool. MANE China General Manager Denis Raffaud created a Work Order by scanning the equipment QR code, thus officially pronouncing the official Go Live of bluebee®. Finally the MANE maintenance team did a complete live demonstration of the system.

Benefits: full traceability, efficient external audits

After using the system for several years, the MANE team gradually discovered its benefits. As all companies in the food industry, MANE faces increasing regulatory pressure and constant scrutiny by its customers. In a traditional maintenance organization, external audits can be very demanding in terms of preparation and documentation: papers are sometimes lost for various reasons and the accuracy of records may be questioned. The mobile-driven Maintenance 4.0 solution used by MANE has effectively solved these pains.

First, in the system, all equipment information and related technical documents are available, daily work records are complete and traceable and all safety-related records are also verifiable. Second, through KPIs and reports, equipment availability, MTBF and MTTR and other related indicators are immediately available. In the system, all information related to a certain piece of equipment can be retrieved quickly based on the equipment code, which greatly reduces the time required for the audit. As a result, MANE has received praises from its external auditors.

According to Mr. Gao, Maintenance Supervisor of MANE Shanghai: “The mobile solution helps us realize paperless maintenance management, freeing us from tons of paper and enabling efficient audits by third-parties. The system allows us to achieve our maintenance goals, as our production capacity continues to increase.”