On the Belt & Road, ensuring maintenance readiness for Algerian power plants

The government of Algeria has launched an unprecedented infrastructure development program to support the North African nation’s urbanization and industrialization. During an inspection tour at the end of 2017, Energy Minister Mustapha Guitouni declared: “Since 2000, the State has invested USD 150 billion in the construction of power plants nationwide. The national production capacity has increased from 3,900MW to now 18,000MW.” Algeria’s current 10-year plan (2015-2025) calls for an additional 27,800MW capacity increase.

Recognizing the strategic importance of maintenance, Sonelgaz, the state-owned power company, has requested the CMMS to be included in all new projects: EPC companies have the responsibility to deliver all technical data in the CMMS and to ensure the system is used from day one. Siveco China, partner of choice for Asia-based EPCs, was selected to provide the CMMS for contracts awarded to Korean and Turkish construction groups.

Powering infrastructure development in Algeria

Ain Arnat 1,200MW Combined Cycle Power Plant

EPC: Hyundai Engineering & Construction (Korea)

Biskra 450MW Simple Cycle Power Plant

EPC: Hanwha Engineering & Construction (Korea)

Boufarik 750MW Simple Cycle Power Plant

EPC: GAMA Power Systems (Turkey)

Jijel 1,300MW Combined Cycle Power Plant

EPC: Hyundai Engineering & Construction (Korea)

Oumache 1,300MW Combined Cycle Power Plant

EPC: Hyundai Engineering & Construction (Korea)

Kais 1,266MW Combined Cycle Power Plant

EPC: GS Engineering & Construction (Korea)

Naama 1,163MW Combined Cycle Power Plant

EPC: Samsung C&T (Korea)

Siveco China’s projects scope

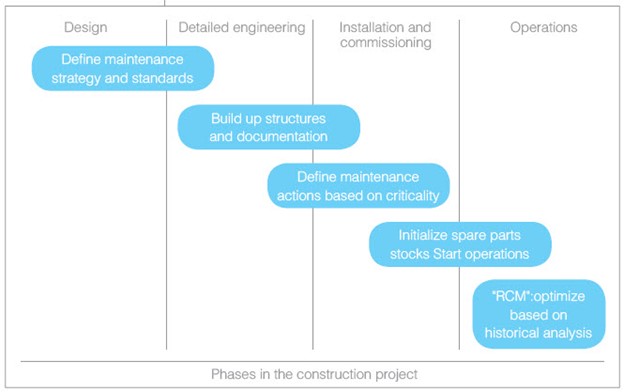

Based on a long experience of greenfield infrastructure projects all over the world, Siveco China has developed a specific expertise working alongside EPC companies and their equipment suppliers during the construction phase, ensuring smooth transfer of technical documentation from construction to operation, supporting plant commissioning and start-up with an accurate technical database and enforcing good maintenance practice from day one. The figure summarizes the Siveco approach for maintenance preparation during a construction project.

For all the projects, overall program management, project management, system configuration and data engineering services are performed by the Siveco Shanghai office, while a certified partner in Algeria provides training and long term support. Thanks to the successful track record, Siveco is already pre-selected as the CMMS supplier for all upcoming projects in the country.

Benefits

The Siveco China approach provides benefits to both EPC companies and plant owners:

- No headache for the CMMS part of the scope.

- One supplier for both CMMS (IT) and data preparation (maintenance engineering) – turnkey project.

- For owner, ensuring maintenance readiness from day one, with significant cost savings and major indirect savings.

- Worldwide coverage, working with EPCs and owners all over the world.

- Very good understanding of EPC project cycle and constraints.

- China’s largest maintenance consultancy, the only ISO 9001-certified maintenance engineering and CMMS supplier in Asia. Our engineers all speak fluent English and have experience working in international environment.

- A strong methodological framework is offered through international standards (e.g. IEC 81346, ISO/TS 16952-10 new KKS, ISO 14224, ISO 55000).

For more information of Siveco China’s approach to greenfield projects, see this article https://www.sivecochina.com/en/services/greenfield-projects/.