Recap of Siveco projects launched in 2014, focus on multisite process plants

For this first newsletter after the Chinese New Year, we would like to recap some key projects launched during 2014, with a focus on process plants: power generation, waste and water, chemicals and oil and gas.

Siveco China has developed specific expertise delivering CMMS-based maintenance improvement projects for large multisite organizations that have their regional headquarters in China and sites all over the Asian region.

The projects also illustrate the built up of the maintenance organization during the construction of a plant, a concept that Siveco has pioneered in China since the company was setup in 2004.

Ain Arnat 1200MW Combined Cycle Power Plant

Industry: power generation

Location: EPC in Korea, plant in Algeria

Scope: turnkey CMMS (Coswin 8i) during construction

Siveco China was selected to deliver its CMMS Coswin 8i for the 3x400MW Ain Arnat combined-cycle gas turbine power plant currently under construction in Algeria. Siveco China is working alongside the EPC (Hyundai Engineering & Construction) and its DCS supplier (Yokogawa Korea) to setup and implement the CMMS before plant startup, including data preparation performed in China, with regular meetings in Seoul. The complex data preparation job is still ongoing, for final onsite delivery before production starts in early 2016.

Bostik

Industry: chemicals

Location: Changshu and Guangzhou

Scope: CMMS (Coswin 7i) during construction (Changshu) and for existing operation (Guangzhou)

Leading global adhesive specialist Bostik, now part of Arkema group, implemented a centralized maintenance management system, based on Coswin 7i, for its Changshu and Guangzhou plants. A Core Model was defined during the construction of the Changshu plant, to help structure the new maintenance organization, and was later adjusted during deployment to the existing Guangzhou plant. The project gave both sites the opportunity to benchmark their maintenance practice. During 2014, Bostik was acquired by leading chemical producer Arkema, another multisite Siveco client.

MANE Fragrances & Flavours

Industry: chemicals

Location: Shanghai, future Asia-wide deployment

Scope: CMMS (Coswin 8i) for existing operation

Mane is a leading International producer of fragrances and flavors for the food & beverage and cosmetic industries. The company launched the implementation of CMMS Coswin 8i and mobile inspection solution bluebee® to support the setup of a modern maintenance organization at its Shanghai production plant in March 2014. The project passed Go Live acceptance in September 2014 and has entered its support phase. The yearly maintenance audit was performed by Siveco team in March 2015, showing further improvement potential. Based on this first project, the system is planned for Asia-wide deployment to other plants of the group.

CEPSA (Shanghai)

Industry: chemicals

Location: Shanghai

Scope: CMMS data preparation (SAP PM) during construction

Siveco was selected by Spanish petrochemical group CEPSA to provide SAP Plant Maintenance (SAP PM) data preparation services for their new 400,000 MT/year Phenol and Acetone production plant, at the time under construction at Shanghai Chemical Industry Park (SCIP). Working from P&IDs, the Siveco engineering team delivered all functional and technical structures for upload to SAP PM, in compliance with international standards (IEC 81346, ISO 14224) and CEPSA internal coding rules. The project was completed in only three months, thanks to Siveco’s extensive experience in this field and the use of automated data handling tools. See this article for more on how Siveco can help clients get more value from SAP PM, with data preparation and other services.

Biskra 450MW Simple Cycle Gas Turbine Power Plant

Industry: power generation

Location: EPC in Korea, plant in Algeria

Scope: turnkey CMMS (Coswin 8i) during construction

Hanwha Engineering & Construction selected Siveco China to deliver the turnkey CMMS for the 450MW simple cycle gas turbine power plant under construction in Algeria. The project includes data preparation services and CMMS configuration performed at the Siveco engineering offices in China, regular coordination meetings with the Korean EPC and its suppliers in Korea, final system setup and end-user training onsite in Algeria, with Siveco’s local partner. The project started in January 2014, Factory Acceptance Test (FAT) was passed successfully in August 2014, after which the system was shipped to the construction site, while data preparation is continuing. The final phase (training, babysitting and go live) will start in time for plant start-up mid-2015.

Degremont

Industry: waste & water

Location: headquarters in Shanghai, sites all over China

Scope: centralized field service solution (bluebee® cloud) for new O&M contracts for existing plants

Degremont is a global water treatment specialist providing engineering and operation services. Siveco provides the central maintenance management platform to support Degremont’s growing Operation & Maintenance (O&M) business in China. The bluebee® suite supports the entire contracting process: engineers use bluebee® surveyor for the initial audit, all data is then uploaded into bluebee® cloud, maintenance supervisors use bluebee® technician for daily recordings. The centralized system allows Degremont to provide expertise and value-added services to its clients. The Degremont-Siveco cooperation was first showcased on one of the company’s food industry client, the Rousselot Da’an Gelatin plant (Jilin province).

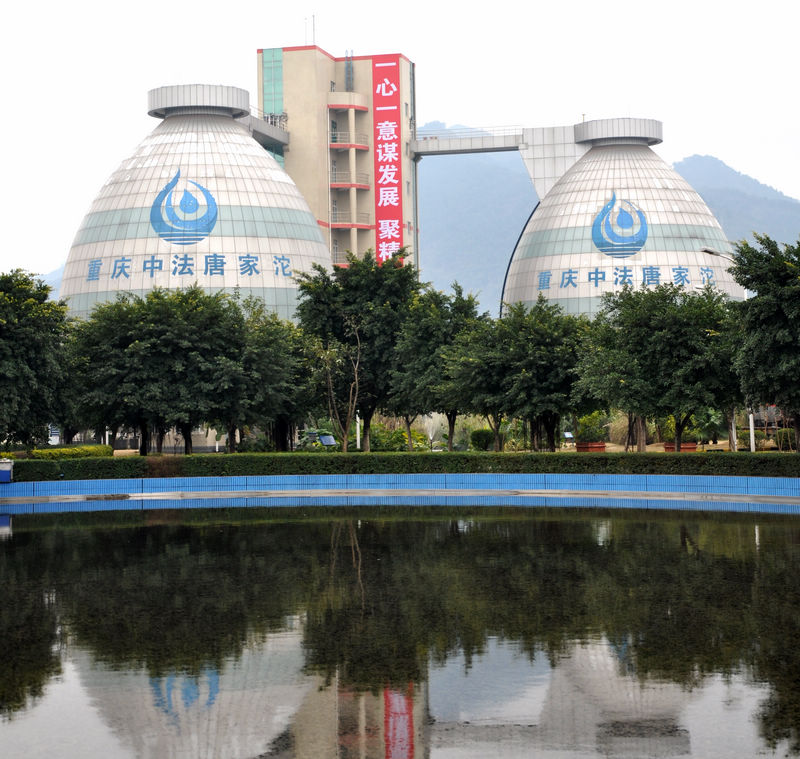

Sino French Water Development

Industry: waste & water

Location: Chongqing and Tianjin

Scope: CMMS (Coswin 7i) and mobile inspection solution (bluebee®) for existing operations

Sino French Water, which provides innovative and sustainable water solutions to over 20 million municipal and industrial customers in China, has been a major Siveco customer for almost a decade. During 2014, two of its Chongqing-based joint-ventures have deployed Coswin 7i and bluebee®, based on the established Group Core Model, that ensures minimum maintenance standards and allows benchmarking between joint-ventures. Sino French Water Tanggu, the company that supplies full water services to Tianjin’s largest development zone, has also deployed Coswin 7i in the same manner. Each of these Sino French Water joint-ventures is a large multisite company on its own, with multiple water treatment plants and water networks.

Baida Pioneer Air Technology

Industry: gas supply

Location: Sichuan, Jiangsu, Fujian and O&M contracts elsewhere in China

Scope: CMMS (Coswin 8i) for existing operations

Beijing Baida Pioneer Air Technology (Baida Air), a leading Chinese provider of industrial gas services, selected Siveco China to implement the Coswin 8i computerized maintenance management system. After a pilot phase completed in August 2014 in Luojiang (Deyang municipality, Sichuan province), the system was deployed to Baida Air own plants in Nantong (Jiangsu province) and Fuqing (Fujian), as well as to various O&M contracts the group has signed with air supply plants owned by its clients. The centralized system helps ensure consistent service and reliable gas supply to Baida Air’s customers, mostly large process manufacturing plants. Every existing and future plants of the group will then use the central maintenance system.

Tianjin Shell Petroleum Storage & Distribution

Industry: oil & gas

Location:Tianjin

Scope: CMMS (Coswin 8i) for new-built facility

Siveco was selected to deliver the Computerized Maintenance Management System (Coswin 8i) for Tianjin Shell Petroleum Storage & Distribution Co., Ltd., a joint-venture of Royal Dutch Shell in Tianjin operating a newly-built 200,000 cubic meters oil storage facility located in the Nangang Industry Zone. A Core Model, based on which the Coswin 8i is being setup, was established to allow Shell’s best practices to be implemented on this site operated by the local joint-venture partner, a process that Siveco has experienced with many other joint-ventures between local groups and leading multinationals all over China. Shell Nangang is set to become another showcase project for Siveco in Tianjin, after Kerneos Aluminates, Danfoss and two Sino-French Water joint-ventures.

SITA Waste Services Nantong

Industry: power generation

Location: Nantong (other sites in Shanghai and Kaohsiung, Taiwan and new projects starting elsewhere in China and Asia)

Scope: CMMS (Coswin 8i) during construction

SITA Waste Services has selected Siveco to implement the Coswin 8i computerized maintenance management system (CMMS) for its new hazardous waste–to energy recovery plant, currently under construction in the Nantong Economic Technology and Development Area (NETDA). Coswin is already in use for several years at SITA other incinerators in Shanghai and Kaohsiung (Taiwan). All projects follow the same Core Model, constantly improved through benchmarking and a continuous improvement process jointly managed by Siveco and SITA. The Nantong project started at the end of 2014 and the CMMS will be operational in time for plant commissioning during the third quarter of 2015.

The projects launched in the process industry during 2014 fully demonstrate Siveco China unique capability to handle multisite clients, with operations in China and Asia, by delivering combined CMMS and maintenance engineering services. In the past ten years, Siveco has accumulated extensive experience with leading customers in the power generation, waste & water industries, oil & gas and chemical industries.

Next month’s article will recap 2014 projects in other industries (automotive, facilities management), as well as maintenance audit contracts.