Smart O&M as a tool for continuous improvement at BEGSE

Background

BEGSE is a solid waste treatment high-tech environmental protection enterprise jointly funded by Beijing Development Environmental Protection (Haidian) Limited (99% share) and Beijing Lvhaineng Environmental Co., Ltd. (1% equity), owned by Beijing Enterprises Environment Group Limited. The company was established in August 2014 with a registered capital of 308 million yuan.

The Renewable Energy Power Plant is located in Beijing Haidian District Circular Economy Industrial Park. It covers an area of 22.75 hectares, with a total construction area of 63,100 square meters. It has a household waste treatment capacity of 2,100 tons/day, approximately 790,000 tons/year, generating approximately 260 million kilowatt-hours/year.

BEGSE was deeply aware of the importance of asset management at the early stage of construction, and contacted Siveco China before the project was officially put into operation, to understand Siveco China’s asset management methodology and business application logic. Based on Siveco China’s successful implementation on waste treatment plants in Shanghai, Taiwan, Nantong, Hong Kong, etc., BEGSE finally chose Siveco China to implement its computerized maintenance solution in the waste-to-energy plant.

Implementation

By defining the “Core Model”, Siveco China has established a comprehensive maintenance management system for BEGSE, including technical data management, HSE management, preventive work planning, spare parts management, procurement management and decision support. Siveco China helped BEGSE to achieve the best maintenance management practices through professional theoretical foundations and systematic training and evaluation.

Specific project goals included:

- Establish a structured plant equipment database (including equipment and spare parts), paying attention to defining equipment types, equipment criticality, and other useful equipment data for vertical and horizontal reliability analysis

- Standardize the work order feedback process, to enable SDCA (Symptoms, Failures, Causes and Measures) analysis to gradually build-up a historical maintenance knowledge base and gradually improve the skill level of the entire maintenance team

- Define and implement preventive maintenance plans (frequency, actions, personnel, spare parts) to ensure equipment availability and safe production

- Build a systematic reporting system, coach the maintenance team to use the reports and performance indicators that meet international standards to carry out continuous improvement work

- Establish a complete inventory and spare parts management mechanism and correlate it with actual maintenance work to provide a basis for safety stock and spare parts procurement plans

- Implement clear procurement practices, from purchase requisition to purchase order, linked with the inventory system.

The CMMS project of BEGSE was launched on September 5, 2016, and the system put online on January 20, 2017. Both the management methodology and its implementation in practice were well received by the top managers of Beijing Enterprises.

Achievements

Siveco China helped BEGSE to optimize its asset management system, from both top management level and working levels:

Management level:

- Help BEGSE to formulate equipment management strategies and define maintenance standards to ensure that they are systematically implemented in on-site work;

- Build a standardized KPI and reports system, and accurately monitor the operation and maintenance management performance of the plant

Working level:

- Established a standardized and structured equipment asset database, equipment coding system and fault codes for BEGSE, with specific attention to equipment structures, associated resources, equipment types and criticality, etc. The aim was to have a comprehensive and accurate understanding of the equipment configuration and help the users to quickly access the information needed to carry out their maintenance work efficiently.

- Through standardized work processes, including regular maintenance, corrective maintenance, including failure analysis (SDCA), inventory management, procurement management, BEGSE gradually established a knowledge base of maintenance and repair experience through work order feedback. Over time this virtuous circle feedback loop helped BEGSE improve the skill level of the entire equipment maintenance department, ensure the strict implementation of maintenance plans and standard operating procedures, providing actionable data for decisions.

As part of the project, BEGSE has established a very standardized procurement and inventory management workflow. The system administrator can configure the approval process in Coswin based on financial value according to company regulations and the needs of the different departments, to effectively control and monitor approvals. In addition, end-users can see the status of their requests in a very intuitive graphical display.

The approval process for procurement

The inventory and purchasing departments of BEGSE monitors the business with automatic reports on a daily basis. Over time, thanks to regular analysis and improvement, the plant’s mastery of the Coswin system, and in particular the use of reports, has become more mature: data in the system more accurately reflects the plant’s operation and maintenance and corresponding financial figures.

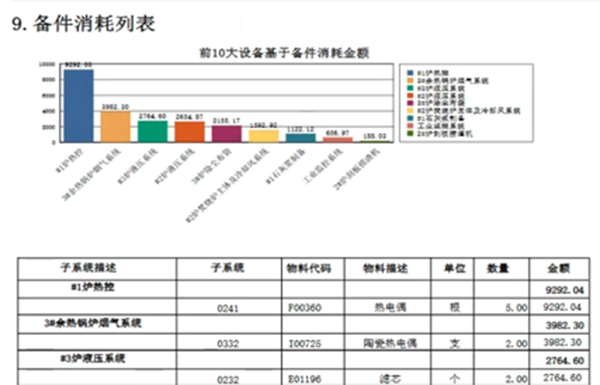

In addition, through graphics and detailed list, users can clearly and intuitively assess plant maintenance performance. For example, by visualizing the top ten equipment in terms of spare parts cost, the maintenance team can take more targeted measures, such as effective preventive maintenance actions for the top equipment. As a result of the initial design phase of the project, Siveco China created customized reports based on specific needs from BEGSE, such as the inventory aging report. This report allows inventory staff to know how long items have been in stock, helping to ensuring the availability of material and thus also improving maintenance efficiency.

Continuous improvement

BEGSE signed an “Enhanced Maintenance Support” contract with Siveco China, so after the initial implementation project was over, the Siveco China team visited the plant every year to conduct annual maintenance assessments. Comparing current system usage with BEGSE’s goals, Siveco China makes suggestions for gradual improvement and monitors the progress of recommended action on a monthly basis. Starting from scratch, through years of cooperation, Siveco China helped BEGSE go from strength to strength: from a new project to a smart plant with a rich asset database and perfect workflows, an advanced benchmark in the entire Beijing Enterprises group. In the future, Siveco China looks forward to more exchanges and cooperation based on Smart Operation & Maintenance with BEGSE and other waste-to-energy plants.

We thank the BEGSE team for their strong support, their commitment and consistent cooperative efforts over the years!