Tianjin water JV benefits from group best practices through Coswin

Tianjin Tanggu Sino French Water Supply

Tianjin Tanggu Sino French Water Supply (“TGSF” www.tjtgsf.com) was formed in 2004 in response to the rapid economic growth of the Tianjin Binhai New Area.

A joint-venture between Tianjin Water Works Group and Sino French Water Investment Company, TGSF provides full water services (water production, sales, construction, distribution network management and related customer services) to one of the largest harbors and the second largest development zone in China. This company has a daily production capacity of 320,000 cubic meters, serving a population of 600,000.

The project: Deploying best maintenance practices through the CMMS

Based on the good results obtained by several other joint-ventures of Sino French Water with municipal water groups elsewhere in China, TGSF selected Siveco to deploy a computerized maintenance management system (CMMS) in order to improve its maintenance practice.

The kick-off meeting was held in October 2014. Two Siveco consultants involved in the project, with support from Siveco’s back-office team, working with Zhao Hongwei, manager in charge of TGSF’s Water Supply department.

A “Group Core Model” had already been established with Sino French Water, incorporating water industry maintenance management best practices, within a management framework in line with the ISO 55000 standard Asset management — Overview, principles and terminology and Sino French group reporting standards.

The first phase of the project consisted in training TGSF team in the Group Core Model and, after a thorough study of the local joint-venture’s maintenance needs, adapting it into a local Core Model and planning its deployment through the Coswin 7i CMMS. In particular, TGSF outsources all its maintenance execution to contractors, both for corrective and preventive maintenance, working under the supervision of TGSF staff.

In TGSF, the coverage of the CMMS includes the management of all the company’s equipment, work management, preventive maintenance, resources management, spare parts and tools management.

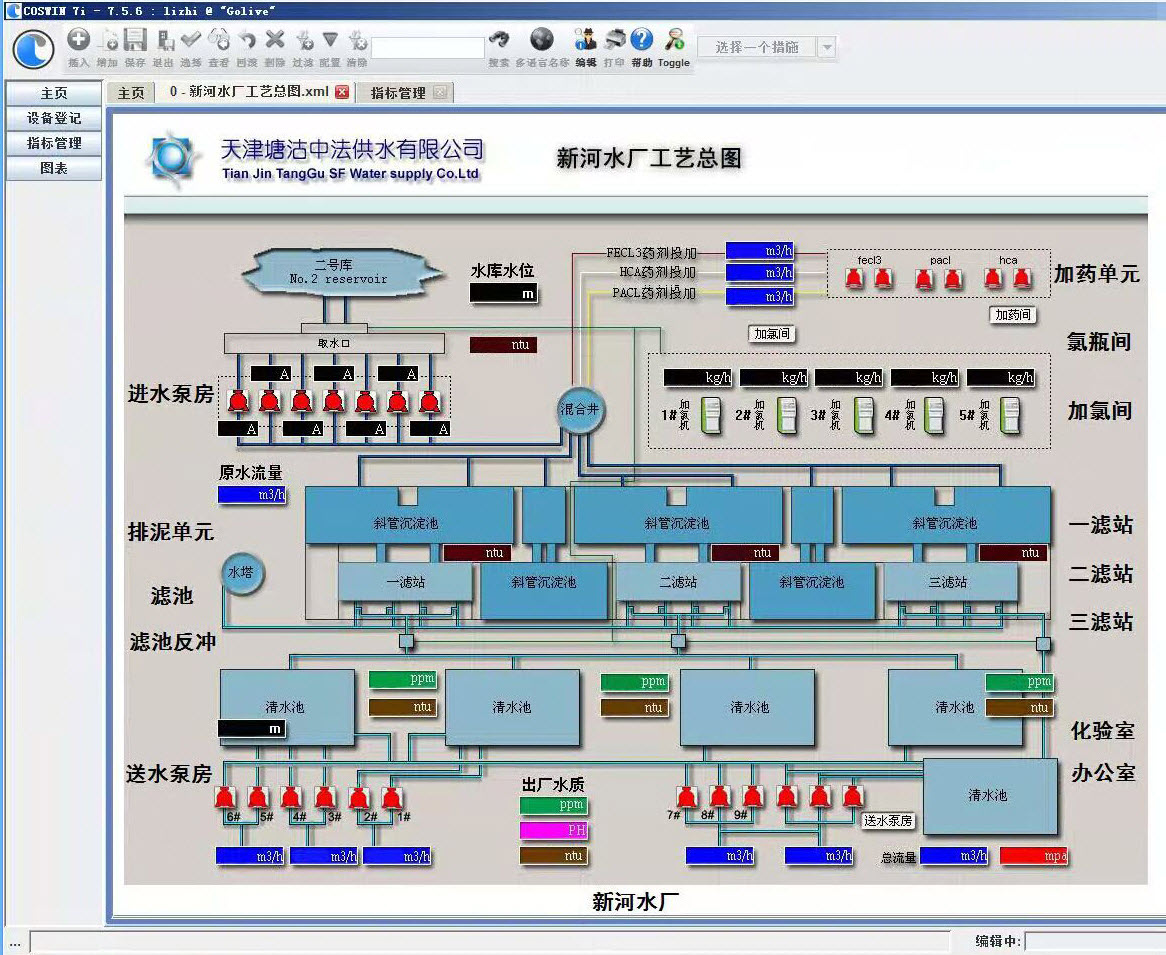

Coswin dashboard of TGSF

The system went live in March 2015.

Benefits obtained

The first benefit obtained from this project has been a smooth implementation of the group Core Model guidelines, using each step of the CMMS project and Coswin itself as a practical training tool. A full ISO 55,000-compliant management system is now in place at TGSF.

TGSF has established standard preventive maintenance activities, based on the know-how of its team, combined with the experience accumulated in Coswin at the other Sino French Water joint-ventures. The CMMS is setup to automatically generate the preventive work plan on a regular basis for its contractors.

Failures are systematically reported in Coswin in a structured manner: end-users can quickly find the related equipment in the system, using the plant layout, the equipment structure or through a search. A failure report can then be created, with Symptom, Defect, Cause and Action (“SDCA”).

By using the system, TGSF is now able to continuous improve its maintenance strategy, to meet its management goals of reducing maintenance cost and enhance production efficiency.

According to Zhao Hongwei, Water Supply Department Manager at TGSF: “The Siveco project has helped us to further enhance our maintenance practice, to learn from the other joint-ventures, but also to contribute our own knowhow and experience to other sister companies in the group. This benchmarking process will allow us to continuously improve ourselves.”