Improvement from CMMS: what do best-in-class companies do

Many companies have implemented technologies for maintenance management (CMMS, EAM, mobile solutions) without obtaining benefits. The most common mistake consists in seeing technology as a “miracle cure”. Once the project fails, technology vendors will often conveniently blame the lack of maturity of the customer’s maintenance team. The solution was right, but the client was not yet ready for it: the objective for the project (a need to improve the organization) becomes the excuse for its failure!

The last “Maintenance in China” survey, conducted in 2017 and covering over 450 companies, provides useful insights. We republish here a summary of the findings and expand on what best-in-class companies (those with the best performance according to their survey results) have done to obtain such results.

The survey

The “Maintenance in China” survey is a joint project between the Sino-European School of Technology of Shanghai University (UTSEUS) and Siveco China. The 2017 survey received 493 responses, from 453 different companies, with sites located all over China. It is by far the most comprehensive survey of its kind. A benchmarking opportunity for companies operating industrial assets in China, the survey also offers interesting insights in the changing role of maintenance, long underestimated, as the country enters a new phase of its industrial development, moving up in the value chain, with increasing automation, robotization and focus on sustainable development, embodied in such concepts as the China Dream and Made in China 2025.

The questionnaire was aligned with the ISO 55000:2014 family of Asset Management standards, now also available as Chinese standard GB/T33172-2016 (approved by the Standard Administration of the People’s Republic of China (SAC) on October 13, 2016, effective from May 1, 2017 under the names: GB/T 33172-2016资产管理, 综述、原则和术语,GB/T 33173-2016资产管理, 管理体系 要求, GB/T 33174-2016资产管理, 管理体系 GB/T 33173应用指南).

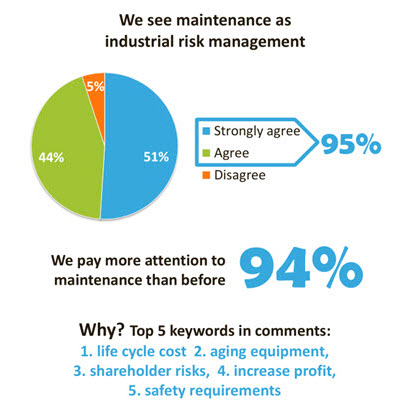

Greater awareness of the importance of maintenance

Responses show great awareness of maintenance, more particularly among Chinese infrastructures and utilities, with risk prevention as a key driver.

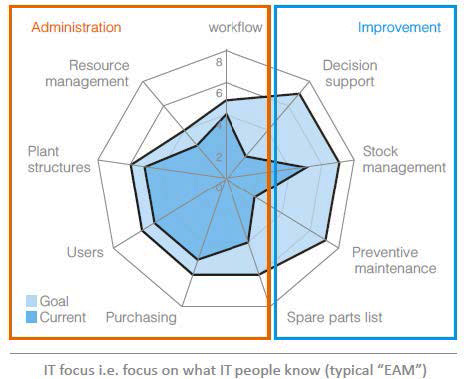

Execution however is still lagging: decision support is a weak area, making it difficult to close the “feedback loop” as per the ISO 55000 (or GB/T 33172) Asset Management standard.

IT tools for maintenance

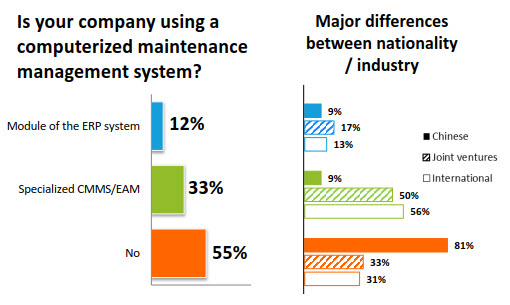

Over half of respondents (and over 80% of local firms, most of them infrastructures or utilities) do not use a CMMS. For multinationals, comparison with 2013 results show that CMMS adoption rate has increased (from 60 to 70%).

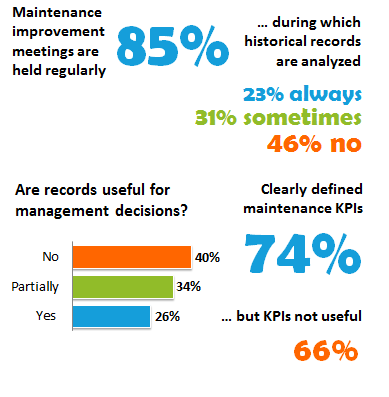

Management tools seldom produce results

When maintenance management controls and tools have been put in place, they seldom produce the expected results in terms of decision support. For example:

Improvement plans

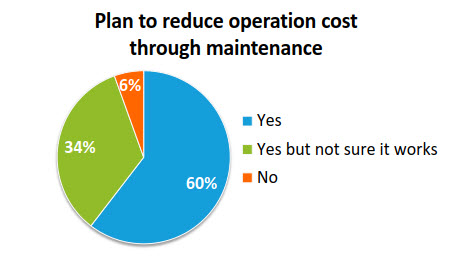

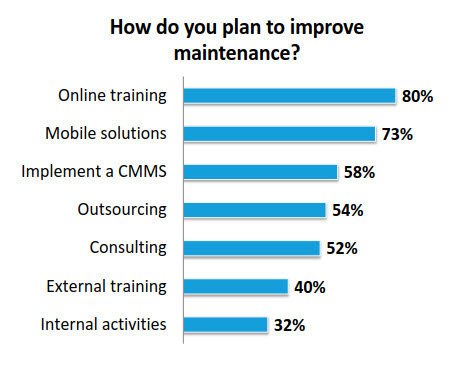

Significant improvement potential exists in terms of breakdowns prevention and productivity gains. 94% of respondents plan to reduce operation cost through maintenance.

Improvement plans often include a range of simultaneous actions. Using CAPEX (investment) is consistent with the goal of reducing risk (rather that OPEX to reduce cost). In 2013, only 47% planned to use CAPEX (the trend at that time was to run smaller OPEX projects aimed at cost reduction).

Differences between multinationals and Chinese firms

In this survey, most local respondents are infrastructure & utilities, while most multinationals are manufacturers, thus differences may reflect industry practices rather than national practices.

The only significant differences found are:

•

Higher response rate from Chinese infrastructure & utility companies, showing stronger interest on the topic of maintenance from local firms.

•

Lower penetration of CMMS technology among local firms: 81% of Chinese infrastructure & utility companies are not using a CMMS vs. 31% for international manufacturing companies.

We believe and observe that the increasing awareness of maintenance among Chinese infrastructure & utilities firms comes from:

•

Government push for sustainable development

•

Strict HSE regulatory enforcement

•

Promotion of computerization (“4.0”)

What do “best in class” companies do?

Our analysis team could not identify simple correlations between one single factor (CMMS, strategy, etc.) and good performance (high positive response rates related to production impact and spare parts management).

However, companies with the best performance:

•

Have a maintenance strategy

•

See maintenance as risk prevention

•

Have a CMMS

•

Hold regular meetings…

•

… during which historical records are analyzed

Responses from “best in class” companies show that having a CMMS is a key factor. Indeed, for large companies such as our respondents, the amount and complexity of historical data are such that manual processing is not possible. The CMMS also helps manage the entire project.

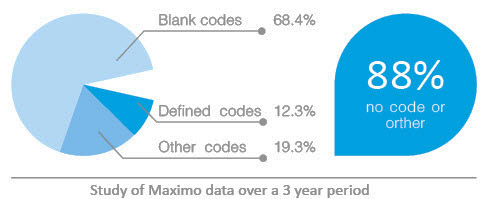

However, responses also show that the CMMS alone is not enough. Based on Siveco’s experience, key steps are often missing: implementation not aligned with strategy, no standardization of codes, no actionable KPIs, no coaching of the team, no taking of “Chinese characteristics” into account.

Other studies show that CMMS projects in China tend to be driven by IT, with no positive impact on business.

The CMMS project can then be used as a “catalyst” to incorporate all activities:

For such a project, ISO 55002:2014 (or GB/T 33174-2016), Section 6.2.2.1 offers useful advice:

There can be benefits in developing the first asset management plan(s) as an interim plan as quickly as possible, using existing information. It helps the organization to understand the strengths and weaknesses of current asset management practices and to identify priorities for the development of future plan(s). It can also help avoid embarking on ambitious data collection exercises before needs are fully understood.

Conclusion

Based on a long experience of “maintenance with Chinese characteristics”, Siveco has developed a unique approach combining maintenance consulting and software tools. While the Chinese market has historically been plagued by IT suppliers without understanding of industrial reality, Siveco is run by maintenance people for maintenance people, focusing on obtaining rapid and sustainable improvement.

Tags: CMMS、maintenance improvement