IoT integration with maintenance system: Siveco China and Schaeffler join forces to release Industry 4.0 solutions

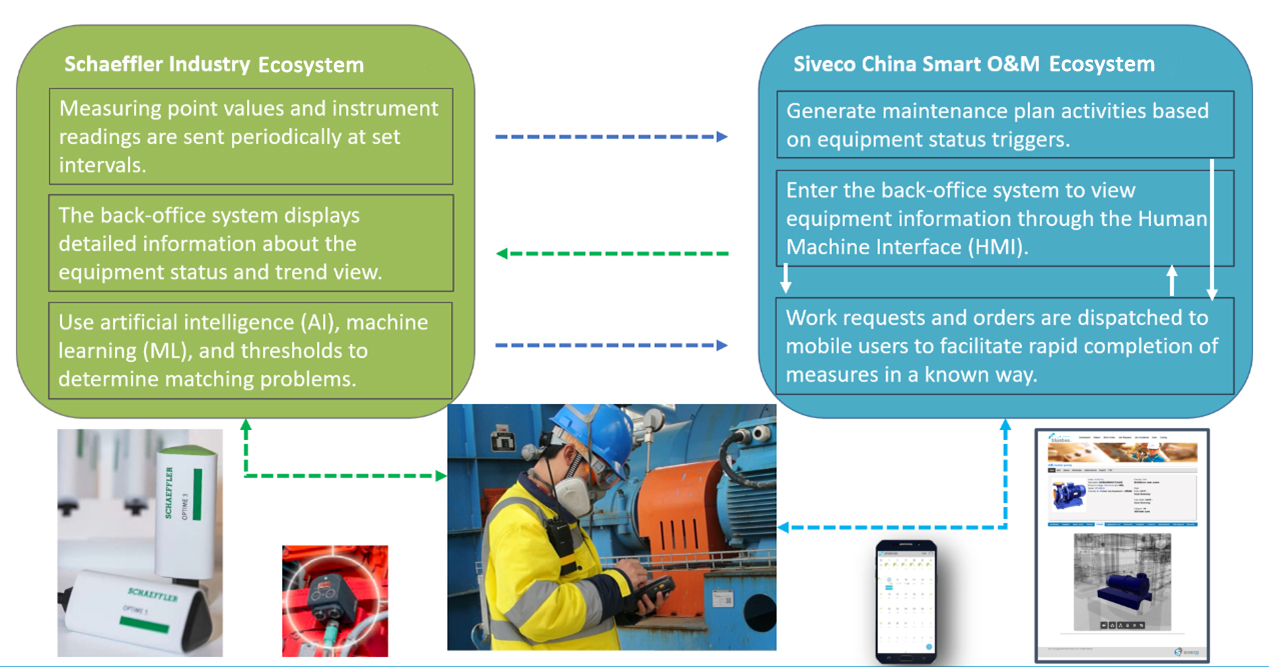

Siveco China and Schaeffler’s Industry 4.0 team established a partnership in China in early 2020. At the time, Siveco China hoped to expand its Smart O&M ecological system to help clients optimize the lifecycle of their assets and ensure regulatory compliance using IT. Schaeffler, on the other hand, was actively shaping digital transformation and the connection of components and systems to boost the efficiency of machines and facilities.

Schaeffler’s systems and components are installed in machines where the most important data is generated. Schaeffler components are equipped with smart sensors, which qualifies them as the important enablers for Industry 4.0.

With each other’s expertise, passion and vision of the future, the two companies have successfully put IoT in Industry 4.0 lifecycle solution into practice.

The accumulated know-how of the two companies in their respective fields has empowered the Smart O&M solution. Alarm and failure analysis based on Schaeffler’s expert algorithm can automatically trigger work requests and maintenance work orders in bluebee® X. Detailed equipment operating parameters can be directly read through bluebee® X, enabling engineers to deeply understand equipment measurement and vibration curves to support analysis and improvements. This solution allows all information such as failure history, historical diagnosis, next planned maintenance activity and trends to be visible in the same platform for better maintenance decisions. The complete solution is showcased at the Schaeffler Industry 4.0 Lab in Shanghai.

This integrated solution is completely carried out through system configuration without any software development, which ensures high system reliability and long-term support and improvement (such as system upgrades, version updates, new labels, etc.), thereby greatly reducing the lifecycle cost of the system.

Advantages of an integrated solution

– Improve equipment availability (i.e. return on investment in equipment)

Equipment loss and failure can be monitored in advance, providing enough time for the technical team to prevent and respond ahead of time and avoid a major impact on operations.

Equipment loss and failure can be monitored in advance, providing enough time for the technical team to prevent and respond ahead of time and avoid a major impact on operations.

– Reduce workload

The inspection is performed by sensors, and the data is automatically analyzed according to the trend chart and threshold. Inspection records can be automatically and directly generated in the format expected by regulators. Technicians can focus on gathering the information they need.

The inspection is performed by sensors, and the data is automatically analyzed according to the trend chart and threshold. Inspection records can be automatically and directly generated in the format expected by regulators. Technicians can focus on gathering the information they need.

– Assist decision-making, based on real and reliable data

The management department and technical team can deeply analyze the inspection details to understand the equipment status under real-time and dynamic settings. Accurate and reliable data information can help the technical team and finance department to make better decisions.

The management department and technical team can deeply analyze the inspection details to understand the equipment status under real-time and dynamic settings. Accurate and reliable data information can help the technical team and finance department to make better decisions.

– Enhance compliance and information transparency, promote trust among stakeholders

The inspection report is made based on the real information collected by the technicians on site and by sensors. Such data information can be traced, verified, and audited at any time, which means that the assets are in good condition and controllable, and safety and environmental risks are also under control.

The inspection report is made based on the real information collected by the technicians on site and by sensors. Such data information can be traced, verified, and audited at any time, which means that the assets are in good condition and controllable, and safety and environmental risks are also under control.

About Schaeffler

The Schaeffler Group is a global supplier of automotive and industrial products, providing high-precision components and systems for powertrain and chassis applications as well as rolling and plain bearing solutions for a large number of industrial applications.