Video Case Study: bluebee® X helps welding material leader achieve Best Practices in Plant Maintenance

The Suzhou plant of an international welding material leader has partnered with Siveco China to implement the bluebee® X Smart Operation and Maintenance solution, achieving tangible maintenance improvement through digital transformation.

read moreStable Operations: How a Leading Hazardous Waste Treatment Company Uses Smart Technology to Navigate Industry Downturns

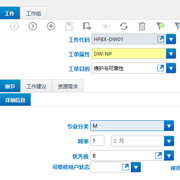

leveraging best operational practices from SUEZ Group and Siveco China’s ISO 55000-based maintenance management methodology, the plant successfully launched the Smart Operations and Maintenance (O&M) system, based on Coswin 8i.

read moreHow bluebee® supports Jiangsu Sino French Water Smart O&M in the implementation of best practices

Both parties conducted in-depth discussions regarding the Smart Operation and Maintenance project. Through repeated communication all the way to final approval, Siveco China ultimately implemented a complete Smart O&M solution that meets the needs of the water supply company.

read moreSiveco China Showcases Smart O&M Solutions at Water Supply High-Quality Development Forum

Since 2004, Siveco China has been actively involved in the water industry market in China, maintaining close relationships with various clients and industry professionals. Recently, the Siveco China Smart Water team participated in the 8th Water Supply High-Quality Development Forum held in Changsha.

read moreIoT for predictive maintenance and the hidden complexity behind its successful, practical, implementation

IoT, Digital Twins, Industry 4.0 have been hot topic for several years already. Vendors tend to make near-magical promises. “Predictive maintenance” is often called a low hanging fruit for such technologies, usually by people who ignore the fundamentals of maintenance.

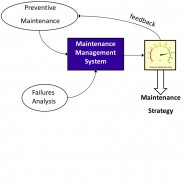

read moreIntegrating FMECA in your Maintenance System

The FMECA is a tool used to systematically analyze potential component failures, their causes and effects and identify the resultant effects on operations so as to take the necessary preventive actions to improve the reliability of facilities, quality of outputs, safety of operations, etc.

read more