COSWIN: Workload management

Planning

COSWIN planning is flexible and powerful: a plan can be theoretical (for what-if type situations) or a practical plan. The two types of plans can be run independently. Multiple plans by multiple planners are available, possible clashes of jobs between plans and handled by COSWIN.

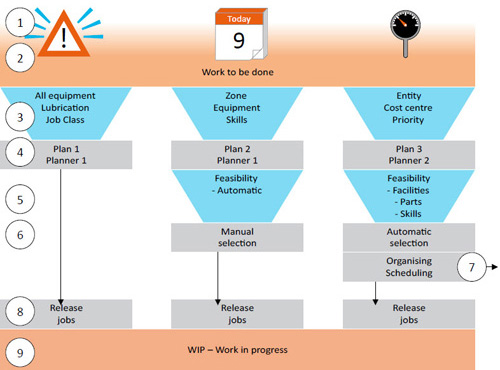

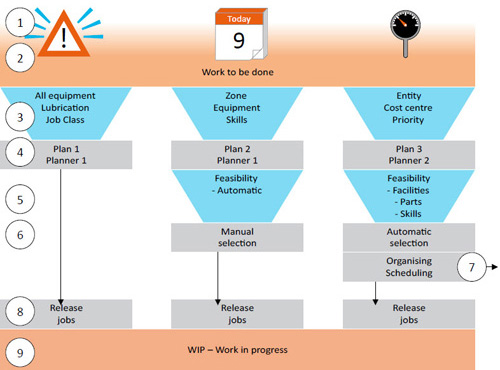

① Jobs collect and backlog because of emergencies, requests or because repetitive jobs come due, by their periodicity, meter or both. Alarms/condition-based events can also generate jobs into COSWIN ② All such jobs collect in COSWIN as due jobs ③ A planner can make one or more plans using various criteria or filtering mechanisms which offer a vast choice of how to draw up a plan. ④ Plan 1 is a simple one, only for lubrication rounds and those jobs are released directly into WIP. Plan 2, also belonging to Planner 1, is more complex, so is Plan 3 that belongs to Planner 2. Note that COSWIN keeps a check on who is working on what plan, there is no “double-counting” of jobs ⑤ Is the work feasible? COSWIN will check the availability of resources such as the trades, or the employees or the skills of people to do the job, as well as the tools, facilities etc. Feasibility checks are automatic but the criteria are selected by the planner ⑥ Jobs cleared as feasible can be selected manually and released as Work Order or can be further refined… ⑦ Plan 3, for example, requires organization and scheduling (see below) and also the functionality of Microsoft Project Management®. Note that any changes in MS Project® are accepted in full by COSWIN when reimported ⑧ Jobs are released into WIP ⑨ The jobs can be emailed, printed downloaded to COSWIN mobile. With a WO number now generated the reservation or withdrawal of parts, tools etc is now possible.

Scheduling, Organising &Project management

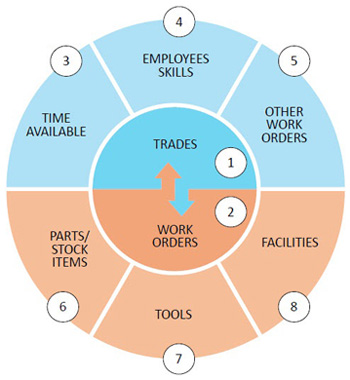

The problem: To schedule work is one of the most complex challenges for a manager and COSWIN provides a full set of tools to help you achieve that. The iterative process required for a solution is summed up in the diagram alongside:

Matching ① trades to work ② or vice-versa is not simple. There are variables which themselves are interdependent as we can see in the outer circle. For example ③ employees have holidays, are ill or otherwise not available. Each employee has a calendar that COSWIN takes into account. Employees ④ have skills and can and cannot do certain work. Also ⑤ in allocating work we have to take account of what work they are already doing and the time required for such work. For the work orders to be accomplished they will need ⑥ stock items, parts, or ⑦ tools or even ⑧ facilities, that is larger plant like cranes, lifting tackle. In other words, to schedule a work order many variables must be taken into account, and each time a decision is made, it affects all of these variables. COSWIN provides you with three solutions.

A. Automatic Scheduling

COSWIN has an automatic scheduling facility that will check for all of the availabilities indicated above and propose a plan. You can influence the way the algorithm works, for example in selecting the work orders COSWIN weights importance according to a) priority of equipment, b) priority of job, c) number of times missed and the total number of hours required for the job. Weight each of these factors according to your own priorities.

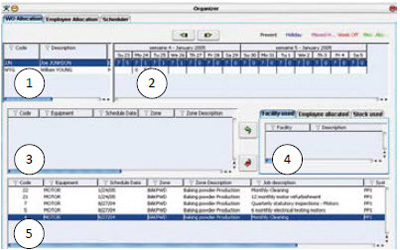

B. Manual organising – by work order

In window ① is the list of employees that can be filtered and at ② is the planning of all available or allocated hours for the employee selected at ①. Note there are two columns, the first column is the hours available, the second the hours already allocated. On top right is the legend from the calendar, a week off etc. At ③ is the list of all the work orders that have been allocated to each employee for the day selected at ②. You may sort each column as required. At ④ the tabs allow for seeing the facilities (plant, equipment necessary for the job), employee allocation and parts or tools used against the current Work Order. The current work order is the one selected at ⑤. Note that the icon allows filtering of each column or data set to the required view.

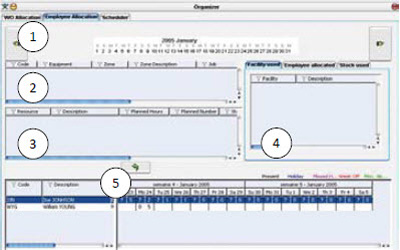

C. Manual organising – by employee

The calendar ① displays the required scheduling date selected (see below). At ② is list of Work order partially assigned to employee(s) and having their schedule data = to the date selected in the calendar selected at ① The window ③ shows a list of resources required for the WO selected in panel ②. At ⑤ is the allocated and available hours of the employee who has been selected just to the left.

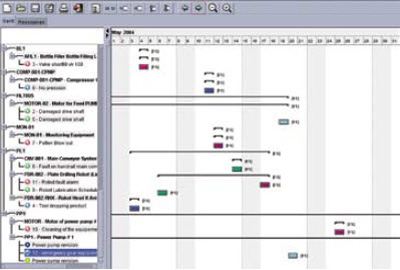

The Gantt Chart

COSWIN offers a Gantt chart view of jobs via the structure view on the left one can immediately see all the jobs planned for a given equipment item. The view shows from the parent down to the last item of equipment affected.

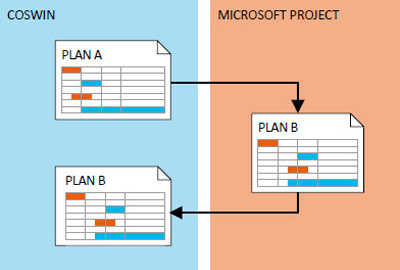

COSWIN & Microsoft Project®

COSWIN integrates perfectly with Microsoft Project. Any plans sent from COSWIN and changed in MS Project are accepted in full back into COSWIN.